Cold Spray Repair vs. Replacement of Aerospace Parts & Components

Aircraft component repair is a rapidly evolving field. With the relatively recent discovery of innovative cold spray repair, aerospace companies have faster and more cost-effective options for mending parts than replacing them.

According to a report released by Sandia National Laboratories, a couple of the many reasons cold spray repair technology is advantageous is because it improves yield strength and has low ductility.

Nevertheless, because cold spray repair technology is so new, many people understandably want to know how it compares to aircraft component replacements. We’ll showcase five differences and explain why cold spray repair is the better choice.

What is Cold Spray Repair?

Electrochemical attacks are the most common form of corrosion and this type of electrochemical reaction is responsible for most forms of corrosion on aircraft structures and components.

An electrically conductive material, such as water, is required for an electrochemical attack to occur. When metal surfaces of your aircraft come into contact with a corrosive agent through a conductive path, corrosion begins.

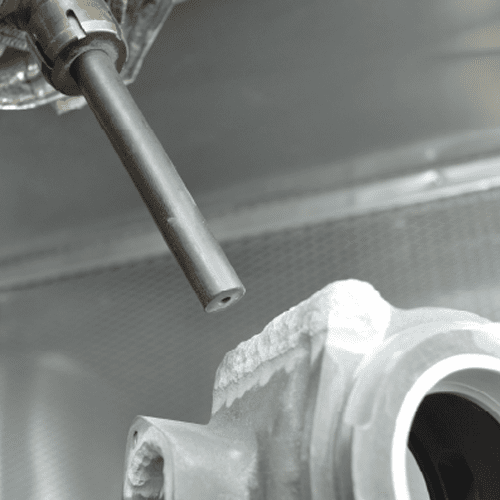

Cold spray repair is an innovative technique to restore damaged aircraft components. In the past, you almost always had to replace a new part when an aerospace component broke. That’s because fixing it required inducing thermal stress, which would strain the aircraft parts. As a result, it increased the chances of safety issues.

Cold spray repair removes this danger. It introduces metal powders at high speeds without applying any heat. As a result, you can restore alloys to their original state cost-effectively and safely.

Many alloys can successfully forgo replacement by using cold spray repair. Examples include but aren’t limited to:

- Aluminum

- Copper

- Stainless Steel

- Titanium

The Advantages of Aerospace Cold Spray Repair vs. Replacement

Below are five reasons why aerospace companies choose cold spray repair instead of part replacements.

You’ll Save Money

Looking for opportunities to save money is a priority for every aircraft company. Cold spray technology will help you achieve this through several means. They include:

- Being cheaper than replacing parts

- Extending your equipment’s lifespan

- Paying fewer labor costs

Even if you need an overhaul service, aircraft component repair with cold spray technology offers a more competitive price than part replacements. Furthermore, you’ll spend less money on labor costs since the portable cold spray machine doesn’t require as many hands as aerospace part replacements often do.

You’ll also benefit from cold spray’s long-term duration. In fact, cold spray technology often outperforms the longevity of new parts before needing maintenance.

Faster Turn-Around Time

Cold spray technology can offer a much quicker turnaround than part replacement does. That’s because many components have long lead times, and using cold spray repair can be a much shorter duration before the aircraft is operable again.

On the other hand, aircraft part replacement involves removing the old part and installing the new one. Since this is a labor-intensive process, you’ll often encounter longer wait times for getting a mechanic to work on your aircraft.

In contrast, cold spray technology offers a fast turnaround time for both minor repairs and overhauls. Additionally, since you’ll receive your repaired aircraft quicker, you can get back in the air, putting your aircraft to work again.

Longer Gaps Between Repairs

Despite people coining today’s society as a “throwaway culture,” the reality is that new items aren’t always better. And that’s precisely the case with cold spray technology.

It feels counterintuitive to think that repairing your current aircraft parts with cold spray technology will reduce the maintenance they’ll need compared to if you replaced them with new parts.

However, according to a study performed on cold spray technology, Australian submarines can remain in the water for longer. That’s because cold spray technology reduces the frequency with which they need to make repairs.

Therefore, cold spray technology will help you lessen the time and money you need to spend on aircraft component maintenance.

More Effective at Repairing Larger Parts

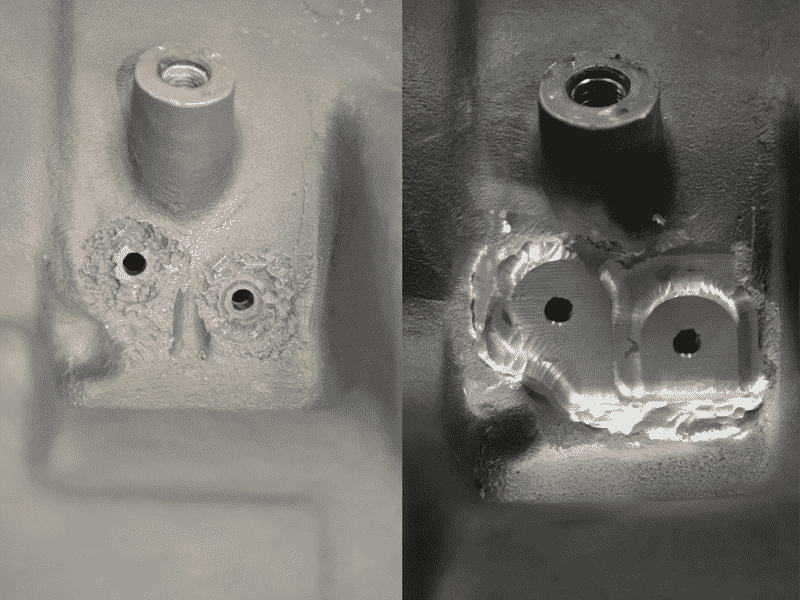

In the past, if you took a large aircraft component to a machine shop, they’d often turn you away, telling you that you need to replace it with a new part. But thanks to cold spray technology, you can now effectively repair large components.

That’s because the cold spray system can increase its scale, offering safe and fast repairs. The technology is excellent at handling large, flat surfaces that need coating. It also performs equally well coating and repairing small crevices.

Furthermore, you can quickly move a cold spray system around your large aerospace parts. As a result, coating these components is easier and faster.

Superior Safety

When you bring your aircraft to a repair station, safety and reliability are likely your top priorities. Safety was why many companies chose to replace their aerospace parts instead of repairing them in the past.

Nowadays, cold spray technology is a durable and reliable choice for your aircraft component repairs, playing on an equal field as part replacements.

Environmental safety is another aspect to consider when comparing cold spray technology and component replacement. That’s because replacing aerospace parts leaves a damaging impact on the environment; it uses up unnecessary resources and contributes to overworked landfills.

In contrast, cold spray repairs reduce your company’s ecological footprint.

At Mid-America Aerotech, we offer you all of these advantages. By harnessing advanced cold spray technology, we provide competitive quotes, faster service, and high safety standards. Get in touch with us for a free quote and discover why we are the number one choice for so many commercial aircraft companies.

Knowing If Aircraft Component Repair Is Right for You

Cold spray technology helps restore damaged aircraft components in a way that was inconceivable a couple of decades ago.

Choosing to repair your aircraft parts with cold spray technology instead of replacing those parts is an excellent fit for companies seeking to:

- Reduce costs

- Repair large parts

- Get your aircraft back to work quicker

- Reduce how often you need to make repairs

- Have peace of mind with safety track records

Are You Ready to Use Cold Spray Technology?

Fast and safe commercial aircraft repairs are at the forefront of Mid-America Aerotech’s mission. Our advanced cold spray technology and competitive prices make us leaders in the industry.

Contact us today for a free quote. Our experienced team will demonstrate why so many commercial aircraft companies choose Mid-America Aerotech for their cold spray repair needs.